- #Abb robotstudio t gripper drivers

- #Abb robotstudio t gripper manual

- #Abb robotstudio t gripper trial

Lenze integrated a MiR200 from Mobile Industrial Robots (MiR) with its existing machinery, enabling fully autonomous transport of finished products between its packing and sorting stations. Performed manually, the task involved a lot of travel and repeated load carrying of parcels, amounting to around 100 packages per operator per day –making it a good candidate for automation with autonomous mobile robots (AMRs). Leading machine manufacturer Lenze Drive Systems (LDS) wanted to improve productivity and enhance ergonomics around product transport processes in its Ruitz, France-based manufacturing facility.

#Abb robotstudio t gripper manual

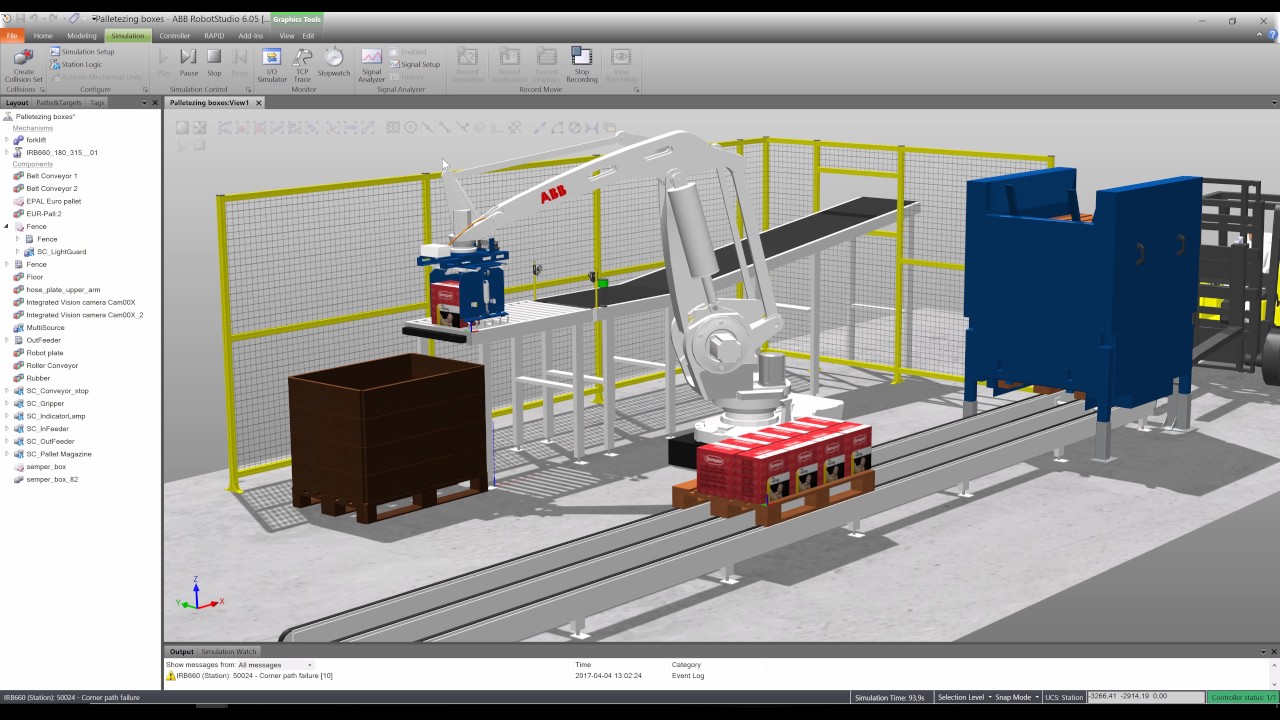

“We went from an exceedingly drawn-out manual process, endlessly pulling modules from bins to find precise matches, to the automated process, which is much easier on our staff.”ĪMRs Drive Productivity, Enhance Worker Safety “The circular robotic storage tower has dramatically improved our remanufactured hybrid battery pack business,” says Michael Menta, Dorman’s vice president of engineering. Capable of identifying likely good matches across each 28-module battery pack and able to store/retrieve one module every eight seconds, the system has helped cut battery build time by 66 percent, increasing the plant’s daily output of finished battery packs by 300 percent. Working closely with an integrator, Dorman Products eventually deployed a solution created in ABB’s RobotStudio simulation software, involving 10 stacks of shelving housing up to 5,000 modules arranged in a ‘decagon’ around a central ABB IRB 4600 six-axis industrial robot.

#Abb robotstudio t gripper trial

Performed manually, operators had to identify the 28 different modules which, only in the perfect combination, creates the optimal replacement battery –a process that could involve up to 100 attempted matches and lots of trial and error. was facing serious challenges around manual reassembly of battery-packs for Toyota Prius hybrid drive vehicles in its Sanford, NC, facility. Meanwhile, automotive battery-pack remanufacturer Dorman Products Inc. and additional sensors to ensure handling is gentle and without collisions. Yokoyama deployed a collaborative robot from AUBO and an RG2 gripper from OnRobot to take care of the lifting, which resulted in a 35% cost reduction compared to human labor, improved quality output and enabled the company to reassign workers to more ergonomic, higher-value roles.Ī linear slide on the robot arm ensures it can reach every position on the shelves, and the end-of-arm-tooling incorporates a gripper from SCHUNK Inc. Previously, the firm had tasked workers with the unergonomic task of loading and unloading of parts into metal stamping machinery but wanted to automate the process to improve productivity and enhance ergonomics for existing staff. “OnRobot’s grippers for collaborative robots and lightweight industrial robot arms are designed to be deployable with a minimum of fuss, which allows companies to address their automation needs quickly and easily and speeds time to ROI,” says Hulgard, citing the case of Yokoyama Kogyo, a Toyota City, Japan-based manufacturer of parts for both the auto and construction industries, which was facing a lack of available labor for machine tending applications. The global manufacturing sector is facing serious challenges including a shortage of available labor and supply chain and inflationary pressures, all of which drive cost-cutting measures and make automation an urgent need for companies of all sizes, says Kristian Hulgard, General Manager Americas at OnRobot.

#Abb robotstudio t gripper drivers

So, let’s take a look at a small sample of recent deployments, alongside the drivers for automation adoption, and the outcomes for end users.Ĭobot & Gripper Deliver Cost Savings, Improved Quality Every year, these technologies drive and support countless real world applications and this year is no exception. Credit: OnRobotįactories and warehouses all over the globe and in every conceivable industry deploy technologies developed by A3 members, with the aim of driving productivity and throughput, staying competitive, and addressing sectoral challenges. Part of the appeal of collaborative robots for certain applications is that following a risk assessment they can be deployed without the need for fencing and can function in close proximity to human workers, as shown here in a recent deployment at Japanese manufacturer Yokoyama Kogyo.

0 kommentar(er)

0 kommentar(er)